Customer needs must be met in order for quality to be achieved. As a result, failing to maintain a sufficient quality level can result in failure. However, maintaining a high degree of quality takes time and work. From the initial inquiry to determine what a potential buyer for a new product truly desires, to the design, specification, controlled manufacturing, and selling procedures.

Fabrics quality control requirements, printed or not, are now required due to the increased demand for clothes, home décor, and upholstery. These are used to guarantee that all materials satisfy design and manufacturing criteria. A spectrophotometer, for example, can be used to evaluate fabric color, while critical control points can provide a product synopsis that includes raw materials, printed fabric durability, and stitch strength. Fabric quality control may also be managed by an industry group that sets standards for physical characteristics and abrasion resistance.

Quality Control in Fabrics

A series of actions or guidelines meant to ensure that a product or service meets particular performance requirements is known as quality control. Quality control’s purpose is to verify that an item fits the needs and criteria of the target market. Quality control also aids a company’s ability to navigate manufacturing and production processes more efficiently, reduce errors and waste, and optimize profit.

Quality control in the fabric sector is very similar to the standard definition given above. It’s a program that’s been in place since the beginning of the textile manufacturing process, from raw fiber sourcing to the final stages of fabric creation.

Fabric products, especially printed fabrics, are frequently scrutinized to see how well they are created, whether they are suitable for their intended use, and whether they fit the expectations of the target market. This usually necessitates a thorough examination of factors like the product’s design specification, target market, and aftercare requirements. Additional variables may be evaluated, such as the quality of stitching and fastening, the product’s aesthetic appeal, and any environmental implications. A thorough sketch of the product may be used to begin the analysis of this data. If you’re thinking of fabrics, check out Create Fabrics and explore their products, they are a wholesale fabric supplier that provides the best quality when it comes to fabric.

If the cloth is cotton, the completed cotton fiber will be swelled, straight, smooth, spherical, and shiny. When you run a moistened finger over cotton fibers, the fibers will lie down if the cloth has a nap.

If the fabric is linen, the fibers will have nodes at regular intervals, similar to a bamboo piece with many joints. When comparing linen and cotton fibers, cotton fiber is whiter in color, softer, and duller, whereas linen fiber is stiffer and creamier.

If it’s silk, the fibers will be straight, very fine, and silky smooth.

If the cloth is nylon, the fibers will appear gleaming.

If the cloth is made of wool, the fiber will be springy, durable, and shiny. If the cloth has a nap, the fibers will spring up when you run a moistened finger over them.

The fibers of rayon fabrics are extremely fine and silky. Although rayon fibers resemble silk strands, they are not as delicate or fine.

Color Measurement

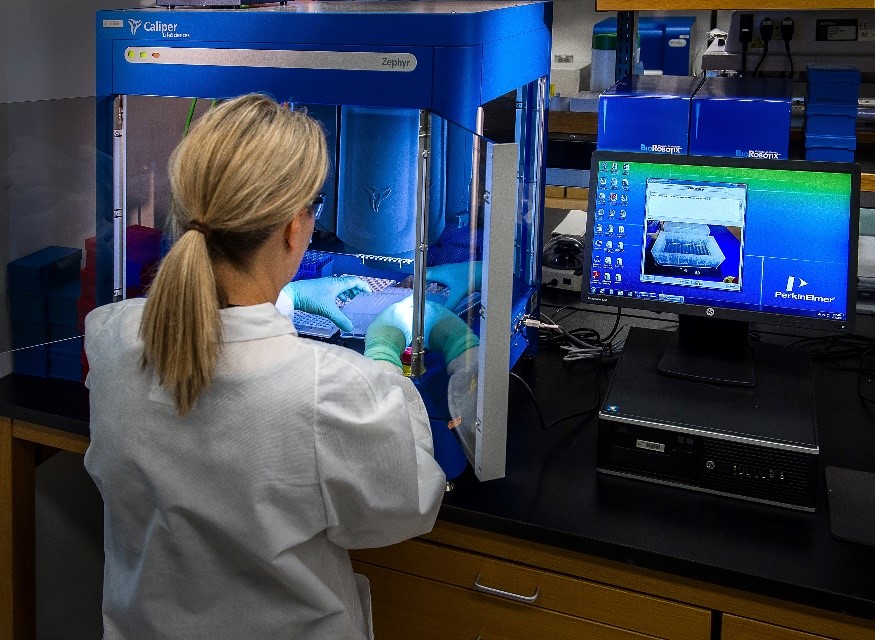

Color measurement techniques are frequently used as the next stage in the quality control of textiles. This is due to the fact that in order to mass make apparel or furniture, colors must typically be repeatable. A spectrophotometer is frequently used to measure the reflected and transmitted color of a fabric. Operators are then given numerical values that correspond to the color of the printed fabric. This enables manufacturers to evaluate whether the dying process needs to be tweaked, how well a fabric will endure exposure to the weather, and what formula is required to reproduce the color in future production.

Test for Accuracy

To ensure that indicators fulfill intended performance, critical control points frequently provide a product summary. This technology can verify and monitor accuracy from the design stage through the manufacturing process when making textiles. For example, the prototype, which is a design sample of the desired product, could be examined for material and component behavior, as well as assembly procedures, prices, and suitability. Operators can evaluate width, weight, and fiber content using raw materials, which are also popular CCPs. The printed fabric may also be tested for durability, wrinkle resistance, and shrinkage, depending on the intended end-use of the product.

Test for Manufacturing Specifications

CCP tests for stitch and seam strength are common during production to verify they match manufacturing specifications. Allowances for seams can also be evaluated to see if they match the planned tolerance. Size, fit, and printed fabric aesthetic appeal may be checked on the final product, which often represents the fruits of textile quality control.

Flame Resistance

A vertical test, in which fabric is placed on a holder and exposed to an open flame for a set amount of time, can be used to determine flame resistance. After the flame has been extinguished, the char length of the test sample can be compared to local or national standards to determine a classification. The cloth can be rubbed with squares of white cotton fabric under regulated pressure for a certain number of times to determine colorfastness. After that, the amount of color transferred to the white test squares can be compared to a control chart to determine a rating.

Ultraviolet Light Resistance

Another significant part of fabric quality management is UV light resistance. The printed fabric may be exposed to light that mimics the sun’s rays for this measurement. After a certain amount of time has passed, the fabric swatch can be compared to a grayscale to determine the degree of fading. Brush pill, breaking strength, and seam slippage tests can all be used to determine physical qualities. Abrasion can be tested by rubbing a fabric in a figure-eight motion with a piece of wool cloth on a flat surface.

Whether you choose to outsource your quality management processes or do them in-house, ensuring that your printed fabric is top-notch will set you apart from low-quality companies because you’ve gone above and beyond to ensure that your clothing is not just attractive but also durable.